Leather-origin & Tannin

-

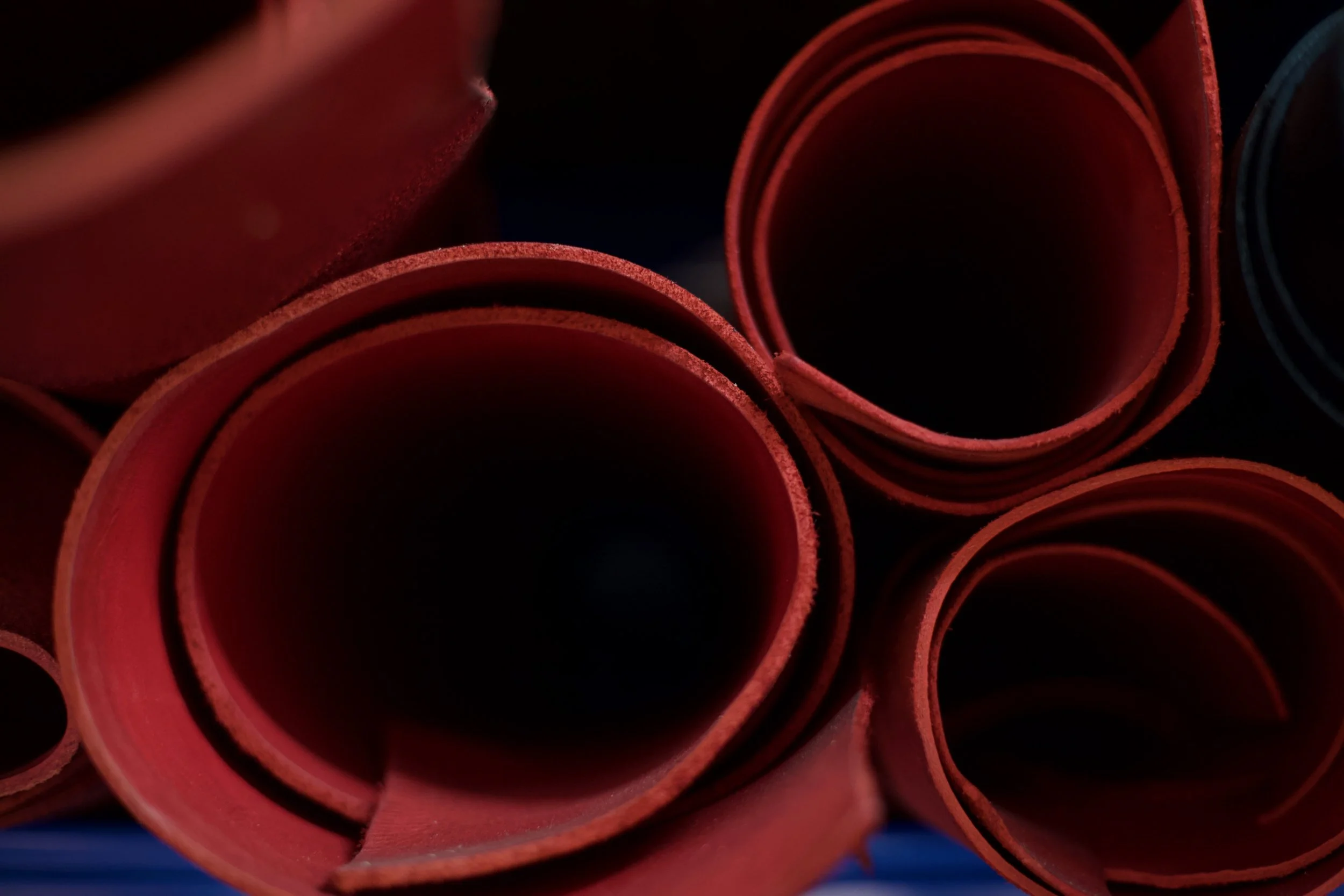

Leather Origin

We source our leather from Leather Tannery Conceria 800 in Florence, Italy, which meets LWG (Leather Working Group) standards.

Conceria 800 dedicates its production to leather hides, processed with vegetable and metal-free tanning, through the use of tannins, oils and fats of organic origin.

Sensitivity, experience and manual skills are skills expressed thanks to the qualities that only the work of man can guarantee.We work with dedication the best European rawhides, respecting the production processes rooted in time.

Each single product is a unique artisan masterpiece, thanks to the skill of our master tanners who use hand-antiquing techniques and natural fly-spooling.For more information: Conceria 800

-

Vegetable Tannin

Using pigment from trees such as mimosa, chestnut and quebracho give each hide exceptional nuances, which tend to resurface and transform in an irreproducible way over time.

This constant interaction between nature, science and craftsmanship allows us to respectfully innovate the ancient, to create products with eternal charm.

To learn about vegetable-tanned leather, watch this video.

-

Sustainability

Our commitment goes beyond the simple tanning of leather. We want to create the perfect balance between our artisanal heritage and responsible innovation.

Sustainability is a daily mission, at the heart of everything we do: from a rigorous selection of the best European leathers , to the use of vegetal tannins from a variety of trees such as mimosa, chestnut, quebracho and oak.Every step in our process is guided by respect for the environment and society .

Our mission is to create quality products while contributing to building a more sustainable and fairer future for all, hyde after hydeConceria 800 places these principles at the basis of each phase of its production cycle:

SUPPLY

Exclusive purchase of raw hides from the food industry, thus ensuring a new life for waste by-products that would otherwise be treated as “special waste”.

Our procurement process thus ensures a circular economy process, helping to reduce environmental impact.PRODUCTION PROCESS

ISO 14001 certified company focused on reducing energy use. All electricity comes from renewable sources. The company uses automatic dosing systems for managing chemicals and water, minimizing waste.

WASTE MANAGEMENT

Conceria 800 guarantees careful segregation, handling and management of all waste from its production cycle, thus promoting recycling.

100% of waste water is sent to the consortium purifier, equipped with cutting-edge technology for water recovery treatment.TRANSPORT

Conceria 800 pays particular attention to reducing fuel consumption, in favor of the use of renewable energy sources.

For this purpose, it has equipped itself with electric vehicles, which guarantee less environmental pollution.